Manufacturing

Axis Manufacturing helps manufacturers schedule, plan, and process manufacturing orders. With the work center control panel, put tablets on the shop floor to control work orders in real-time and allow workers to trigger maintenance operations, feedback loops, quality issues, etc.

See also

Axis Manufacturing helps manufacturers schedule, plan, and process manufacturing orders. With the work center control panel, put tablets on the shop floor to control work orders in real-time and allow workers to trigger maintenance operations, feedback loops, quality issues, etc.

See also

Axis Manufacturing helps manufacturers schedule, plan, and process manufacturing orders. With the work center control panel, put tablets on the shop floor to control work orders in real-time and allow workers to trigger maintenance operations, feedback loops, quality issues, etc.

By using Axis Manufacturing, users can manage their manufacturing processes, including bills of materials, routings, work orders, and more.

Axis Manufacturing helps manufacturers schedule, plan, and process manufacturing orders. With the work center control panel, put tablets on the shop floor to control work orders in real-time and allow workers to trigger maintenance operations, feedback loops, quality issues, etc.

By using Axis Manufacturing, users can manage their manufacturing processes, including bills of materials, routings, work orders, and more.

A bill of materials (or BoM for short) documents specific components, along with their respective quantities, that are needed to produce or repair a product. In Axis, BoMs serve as blueprints for manufactured goods and kits, and often include production operations and step-by-step guidelines, as well.

BoM setup

To create a BoM, go to and click New.

Next, set the BoM Type to Manufacture this Product.

Then, specify required components and, if necessary, define any manufacturing operations.

Tip

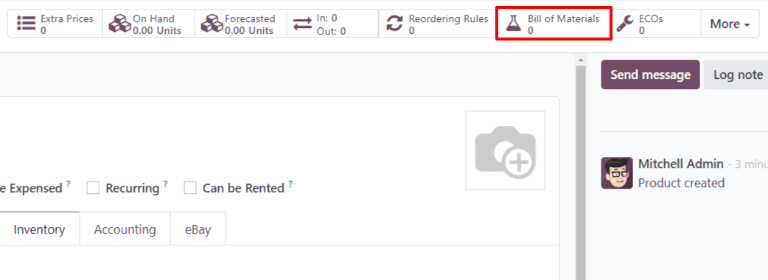

Individual BoMs can also be quickly accessed or created by clicking the Bill of Materials smart button on any product form, as accessible through the Sales, Inventory, and Manufacturing apps, as well as through any internal links where a product is referenced (such as in a field or a line item).

BoM for Drawer, displaying the Components tab.

See also

Components

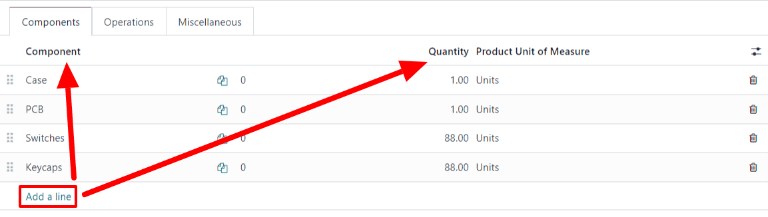

In the Components tab of a BoM, specify components used to manufacture the product by clicking Add a line. From the Components drop-down menu, select from existing products or create a new product by typing the name and selecting either the Create ” “ option to quickly add the line item, or the Create and edit… option to add the component and continue to its configuration form.

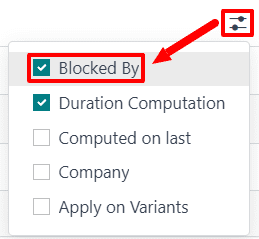

Optionally, access additional fields by clicking the (settings adjust) icon to the far-right of the Components tab. Tick the checkboxes for the following features to enable these columns:

Apply on Variants: specify which product variant each component is used in. When the field is left blank, the component is used in all product variants.

Consumed in Operation: specify the operation using the component. Useful for determining manufacturing readiness.

Manual Consumption: tick the checkbox to force operators to check the Consumed checkbox on a manufacturing order (MO).

Not doing so triggers the Consumption Warning error message, where the consumed component quantity must be manually inputted. Otherwise, the operation cannot be completed.

Operations

Add an operation to a BoM to specify instructions for production and register time spent on an operation. To use this feature, first enable the Work Orders feature by going to . In the Operations section, tick the Work Orders checkbox to enable the feature.

See also

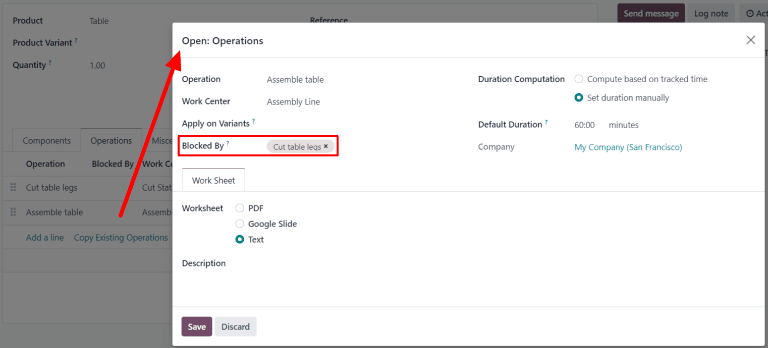

Next, navigate to the BoM by going to and selecting the desired BoM. To add a new operation, go to the Operations tab, and click Add a line.

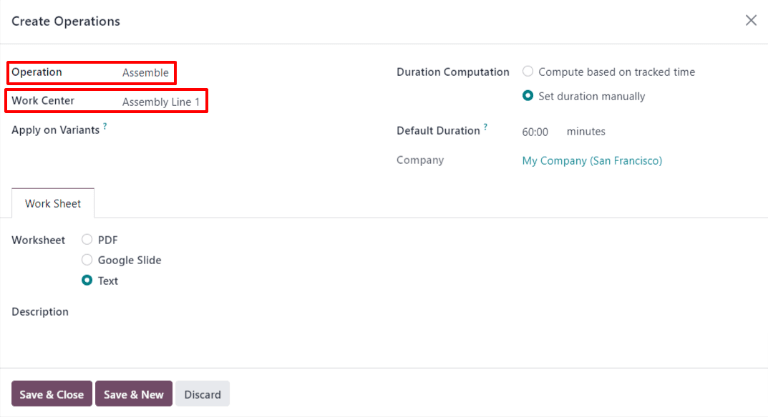

Doing so opens the Create Operations pop-up window, where the various fields of the operation are configured:

Operation: name of the operation.

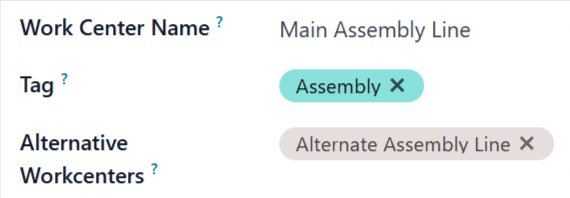

Work Center: select existing locations to perform the operation, or create a new work center by typing the name and selecting the Create ” “ option.

Apply on Variants: specify if this operation is only available for certain product variants. If the operation applies to all product variants, leave this field blank.

Duration Computation: choose how time spent on the operation is tracked. Opt for Compute based on tracked time to use the operation’s time tracker or Set duration manually if operators can record and modify time themselves.

Choosing the Compute based on tracked time option enables the Based on last __ work orders option, which automatically estimates the time to complete this operation based on the last few operations. Choosing Set duration manually enables the Default Duration field instead.

Default Duration: estimated amount of time to complete the operation; used for planning manufacturing orders and determining work center availability.

Company: specify the company the BoM is available in.

Include operation details in the Work Sheet tab. Choose PDF to attach a file or Google Slide with public access to share a link. Select Text to type instructions in the Description text field.

Tip

Type / for a list of formatting options and features, including ChatGPT.

Finally, click Save & Close to close the pop-up window. To add more operations, click Save & New and repeat the same steps above to configure another operation.

Note

Each operation is unique, as it is always exclusively linked to one BoM.

Tip

After creating an operation, click the Copy Existing Operations button to choose an operation to duplicate.

Instructions

Important

To add detailed instructions to operations, the Quality app must be installed.

Add specific instructions to an existing operation by clicking the operation’s (list) icon in the Instructions column. The number in the Instructions column shows the number of existing detailed instructions there are for the operation.

On the Steps dashboard, click New to open a blank quality control point form where the new manufacturing step can be created. Here, give the specific instruction a Title and set the Type to Instructions. In the Instructions tab of the form, write out the directions for the step in the operation.

Note

Further customizations can be made here on this form, beyond ordinary instructions, to also include specific types of quality control points that carry specific (or complex) conditions. For more details about quality control points refer the Instruction check documentation.

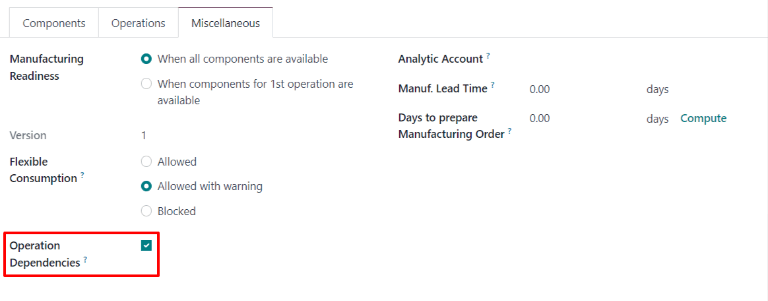

Miscellaneous

The Miscellaneous tab contains more BoM configurations to customize procurement, calculate costs, and define how components are consumed.

Manufacturing Readiness: choosing When components for the 1st operation are available shows the Component Status as a green Not Available, when only the components that are consumed in the first operation are in stock. This indicates that although not all components are available, operators can at least begin with the first operation. Choosing When all components are available displays a red Not Available component status unless all components are in available.

Tip

Specify which operation consumes each component on the BoM in the Manual Consumption field.

Version: displays the current BoM version, visible with the Axis PLM app installed for managing BoM changes.

Flexible Consumption: specifies if components used can deviate from the quantity defined on the BoM. Choose Blocked if operators must adhere strictly to the BoM quantity. Otherwise, choose Allowed or Allowed with Warning.

Routing: select the preferred warehouse’s manufacturing operation type for products produced in multiple warehouses. If left blank, this warehouse’s

Manufacturingoperation type is used by default.Analytic Distribution: select pre-created analytic distribution models from the list to automatically record the cost of manufacturing products in the chosen journal.

Manuf Lead Time: define the number of days needed to complete a MO from the date of confirmation.

Days to prepare Manufacturing Order: number of days needed to replenish components, or manufacture sub-assemblies of the product.

See also

Add by-products to BoMs

A by-product is a residual product that is created during production in addition to the main product of a BoM. Unlike the primary product, there can be more than one by-product on a BoM.

To add by-products to a BoM, first enable the By-Products feature in . In the Operations section, tick the checkbox for By-Products to enable the feature.

Once the feature is enabled, add by-products to a BoM by clicking the By-products tab. Click Add a line, and fill in the By-product, Quantity, and Unit of Measure. Optionally, specify a Produced in Operation for the by-product.

Example

The by-product, Mush, is created in the Grind grapes operation when producing Red Wine.

In order to manufacture a product in Axis Manufacturing, the product must be properly configured. Doing so consists of enabling the Manufacturing route and configuring a bill of materials (BoM) for the product. Once these steps are completed, the product is selectable when creating a new manufacturing order.

Activate the Manufacture route

The Manufacture route is activated for each product on its own product page. To do so, begin by navigating to . Then, select an existing product, or create a new one by clicking New.

On the product page, select the Inventory tab, then enable the Manufacture checkbox in the Routes section. This tells Axis the product can be manufactured.

Lot/serial number tracking

The assignment of lots or serial numbers to newly manufactured products is optional. To optionally assign lots or serial numbers to newly manufactured products, go to the Traceability section in the Inventory tab. In the Tracking field, select By Unique Serial Number or By Lots.

Doing so enables the Lot/Serial Number field on a manufacturing order, or the Register Production instruction on a work order card in the Shop Floor app.

Lot/Serial Number field on the MO.

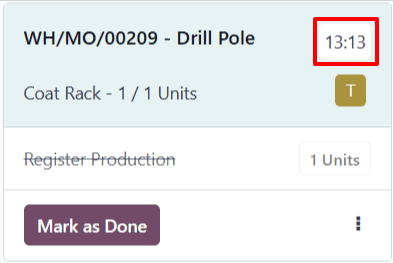

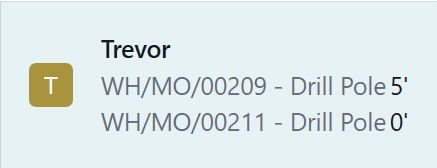

Register Production option to generate lot/serial number on a work order card.

Configure a bill of materials (BoM)

Next, a BoM must be configured for the product so Axis knows how it is manufactured. A BoM is a list of the components and operations required to manufacture a product.

To create a BoM for a specific product, navigate to , then select the product. On the product page, click the Bill of Materials smart button at the top of the page, then select New to configure a new BoM.

On the BoM, the Product field auto-populates with the product. In the Quantity field, specify the number of units that the BoM produces.

Add a component to the BoM by selecting the Components tab and clicking Add a line. Select a component from the Component drop-down menu, then enter the quantity in the Quantity field. Continue adding components on new lines until all components have been added.

Next, select the Operations tab. Click Add a line and a Create Operations pop-up window appears. In the Operation field, specify the name of the operation being added (e.g. Assemble, Cut, etc.). Select the work center where the operation will be carried out from the Work Center drop-down menu. Finally, click Save & Close to finish adding operations, or Save & New to add more.

Important

The Operations tab only appears if the Work Orders setting is enabled. To do so, navigate to , then enable the Work Orders checkbox.

Learn more

The section above provides instructions for creating a basic BoM that allows a product to be manufactured in Axis. However, it is by no means an exhaustive summary of all the options available when configuring a BoM. For more information about bills of materials, see the documentation on how to create a bill of materials.

Axis Manufacturing allows users to manufacture products using one, two, or three steps. When using one-step manufacturing, Axis creates a manufacturing order (MO), but does not generate transfers for the movement of components out of inventory or finished products into stock. Inventory counts still update based on the number of components used and products manufactured, but the act of transferring them to and from inventory is not tracked.

Tip

The number of steps used in manufacturing is set at the warehouse level, allowing for each warehouse to use a different number of steps. To change the number of steps used for a specific warehouse, begin by navigating to , and then select a warehouse from the Warehouses screen.

On the Warehouse Configuration tab, find the Manufacture radio input field, and select one of the three options: Manufacture (1 step), Pick components and then manufacture (2 steps), or Pick components, manufacture and then store products (3 steps).

Important

Products must be properly configured before they can be manufactured in Axis. For details on how to do so, see the documentation on how to configure a product for manufacturing.

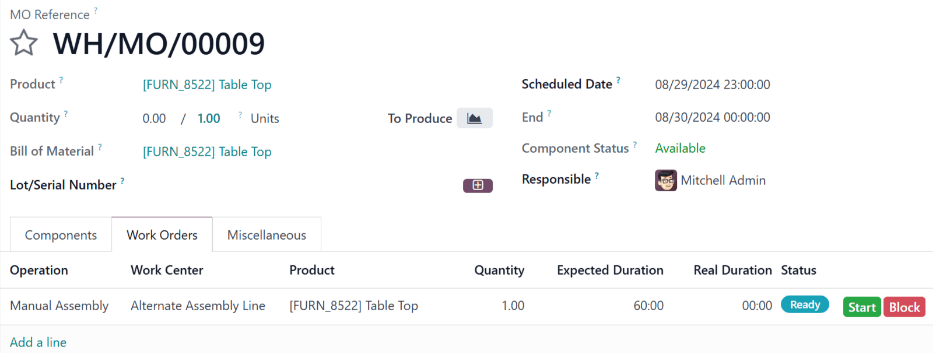

Create manufacturing order

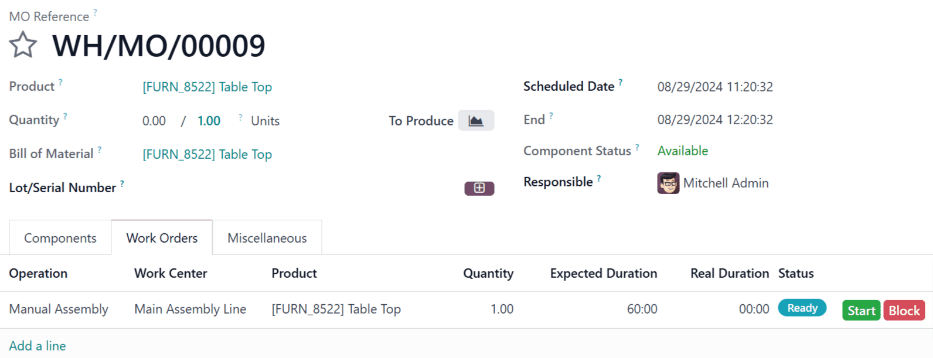

To manufacture a product in Axis Manufacturing, begin by navigating to , and then click New to create a new MO.

On the new MO, select the product to be produced from the Product drop-down menu. The Bill of Material field auto-populates with the associated bill of materials (BoM).

If a product has more than one BoM configured for it, the specific BoM can be selected in the Bill of Material field, and the Product field auto-populates with the associated product.

After a BoM has been selected, the Components and Work Orders tabs auto-populate with the components and operations specified on the BoM. If additional components or operations are required for the MO being configured, add them to the Components and Work Orders tabs by clicking Add a line.

Finally, click Confirm to confirm the MO.

Process manufacturing order

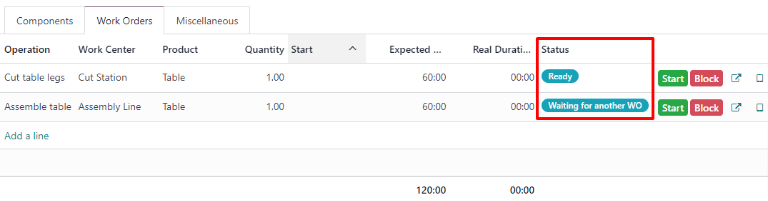

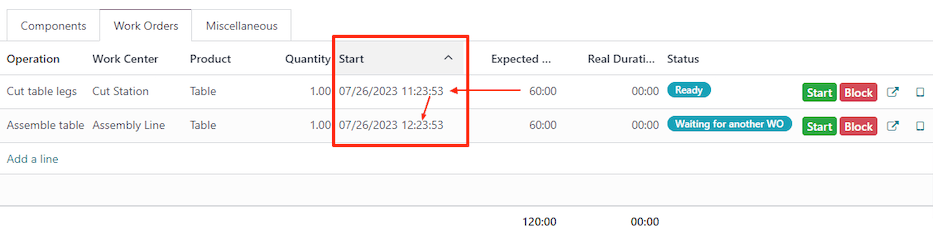

An MO is processed by completing all of the work orders listed under its Work Orders tab. This can be done on the MO itself, or from the work order tablet view.

Basic workflow

To complete work orders from the MO itself, begin by navigating to , and then select an MO.

On the MO page, select the Work Orders tab. Once work begins on the first work order that needs to be completed, click the Start button for that work order. Axis Manufacturing then starts a timer that keeps track of how long the work order takes to complete.

When the work order is completed, click the Done button for that work order. Repeat the same process for each work order listed on the Work Orders tab.

After completing all of the work orders, click Produce All at the top of the screen to mark the MO as Done, and register the manufactured product(s) into inventory.

Shop Floor workflow

To complete the work orders for an MO using the Shop Floor module, begin by navigating to , and then select an MO.

On the MO, click on the Work Orders tab, and then select the ↗️ (square with arrow coming out of it) button on the line of the first work order to be processed. Doing so opens a Work Orders pop-up window, with details and processing options for the work order.

On the pop-up window, select the Open Shop Floor button at the top-left of the window to open the Shop Floor module.

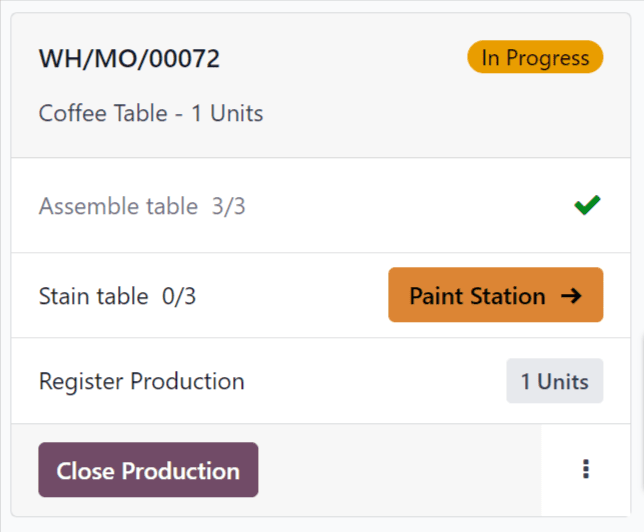

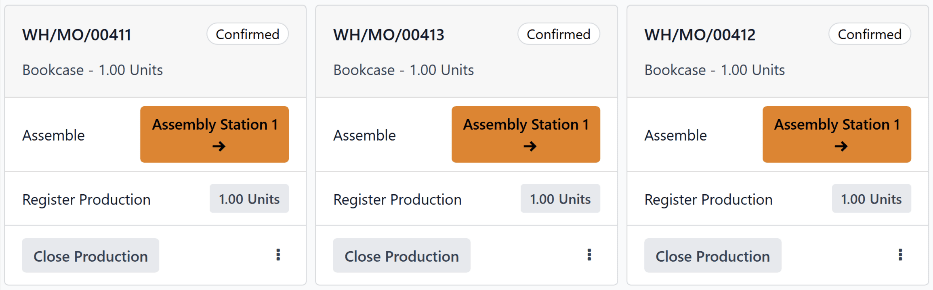

When accessed directly from a specific work order within an MO, Shop Floor defaults to the page for the work center where the work order is configured to be carried out. The page shows a card for the work order that displays the MO number, the product and number of units to be produced, and the steps required to complete the work order.

A work order is processed by completing each step listed on its card. This can be done by clicking on a step and following the instructions listed on the pop-up window that appears. Once the step is completed, click Next to move on to the next step, if any are required.

Alternatively, work order steps can be completed by clicking the checkbox that appears on the right side of the step’s line on the work order card. When using this method, the step is automatically marked as completed, without a pop-up window appearing.

The final step on a work order card is titled Register Production. This step is used to register the number of product units that were produced. If the number produced is equal to the number that the MO was created for, click the # Units button on the right side of the line to automatically register that number as the quantity produced.

If a different number must be entered, click the Register Production step to open a pop-up window. Enter the number of units produced in the Units field, and then click Validate to register that number.

Note

The Register Production step appears on every work order card. It must be completed for the first work order that is processed. After doing so, the step appears as already completed for each remaining work order in the MO.

After completing all of the steps for a work order, a button appears on the footer of the work order card. If any other work orders must be completed before the MO can be closed, the button is titled Mark as Done. If there are no additional work orders to complete, the button is titled Close Production.

Clicking Mark as Done causes the work order card to fade away. Once it disappears completely, the work order’s status is marked as Finished on the MO, and the next work order appears in the Shop Floor module, on the page of the work center where it is configured to be carried out. Any additional work orders can be processed using the instructions detailed in this section.

Clicking Close Production causes the work order card to fade away. Once it disappears, the MO is marked as Done, and the units of the product that were produced are entered into inventory.

After clicking Mark as Done or Close Production, each button is replaced by an Undo button. Click the Undo button before the work order card fades away to keep the work order open.

Tip

This section details the basic workflow for processing an MO in the Shop Floor module. For a more in-depth explanation of the module and all of its features, please see the Shop Floor overview documentation.

Axis Manufacturing allows users to manufacture products using one, two, or three steps. When using two-step manufacturing, Axis creates a manufacturing order (MO) and a pick components transfer, but does not generate a transfer for the movement of finished products into stock. Inventory counts still update based on the number of products manufactured, but the act of transferring them to and from inventory is not tracked.

Tip

The number of steps used in manufacturing is set at the warehouse level, allowing for each warehouse to use a different number of steps. To change the number of steps used for a specific warehouse, begin by navigating to , and then select a warehouse from the Warehouses screen.

On the Warehouse Configuration tab, find the Manufacture radio input field, and select one of the three options: Manufacture (1 step), Pick components and then manufacture (2 steps), or Pick components, manufacture and then store products (3 steps).

Important

Products must be properly configured before they can be manufactured in Axis. For details on how to do so, see the documentation on how to configure a product for manufacturing.

Create manufacturing order

To manufacture a product in Axis Manufacturing, begin by navigating to , and then click New to create a new MO.

On the new MO, select the product to be produced from the Product drop-down menu. The Bill of Material field auto-populates with the associated Bill of Materials (BoM).

If a product has more than one BoM configured for it, the specific BoM can be selected in the Bill of Material field, and the Product field auto-populates with the associated product.

After a BoM has been selected, the Components and Work Orders tabs auto-populate with the components and operations specified on the BoM. If additional components or operations are required for the MO being configured, add them to the Components and Work Orders tabs by clicking Add a line.

Finally, click Confirm to confirm the MO.

Process pick components transfer

After confirming a two-step MO, a Transfers smart button appears at the top of the page. Click it to open the pick components transfer for the MO. This transfer is used to track the movement of components from the locations where they are stored to the location where they are used to manufacture the product.

After transferring the components out of their storage location, click Validate at the top of the transfer, followed by Apply on the Immediate Transfer? pop-up window that appears. Doing so marks the transfer as Done, and updates inventory counts to reflect the quantity of components transferred.

Finally, return to the MO by clicking the WH/MO/XXXXX breadcrumb at the top of the page.

Process manufacturing order

An MO is processed by completing all of the work orders listed under its Work Orders tab. This can be done on the MO itself, or from the work order tablet view.

Basic workflow

To complete work orders from the MO itself, begin by navigating to , and then select an MO.

On the MO page, select the Work Orders tab. Once work begins on the first work order that needs to be completed, click the Start button for that operation. Axis Manufacturing then starts a timer that keeps track of how long the work order takes to complete.

When the work order is completed, click the Done button for that work order. Repeat the same process for each work order listed on the Work Orders tab.

After completing all of the work orders, click Produce All at the top of the screen to mark the MO as Done, and register the manufactured product(s) into inventory.

Shop Floor workflow

To complete the work orders for an MO using the Shop Floor module, begin by navigating to , and then select an MO.

On the MO, click on the Work Orders tab, and then select the ↗️ (square with arrow coming out of it) button on the line of the first work order to be processed. Doing so opens a Work Orders pop-up window, with details and processing options for the work order.

On the pop-up window, select the Open Shop Floor button at the top-left of the window to open the Shop Floor module.

When accessed directly from a specific work order within an MO, Shop Floor defaults to the page for the work center where the work order is configured to be carried out. The page shows a card for the work order that displays the MO number, the product and number of units to be produced, and the steps required to complete the work order.

A work order is processed by completing each step listed on its card. This can be done by clicking on a step and following the instructions listed on the pop-up window that appears. Once the step is completed, click Next to move on to the next step, if any are required.

Alternatively, work order steps can be completed by clicking the checkbox that appears on the right side of the step’s line on the work order card. When using this method, the step is automatically marked as completed, without a pop-up window appearing.

The final step on a work order card is titled Register Production. This step is used to register the number of product units that were produced. If the number produced is equal to the number that the MO was created for, click the # Units button on the right side of the line to automatically register that number as the quantity produced.

If a different number must be entered, click the Register Production step to open a pop-up window. Enter the number of units produced in the Units field, and then click Validate to register that number.

Note

The Register Production step appears on every work order card. It must be completed for the first work order that is processed. After doing so, the step appears as already completed for each remaining work order in the MO.

After completing all of the steps for a work order, a button appears on the footer of the work order card. If any other work orders must be completed before the MO can be closed, the button is titled Mark as Done. If there are no additional work orders to complete, the button is titled Close Production.

Clicking Mark as Done causes the work order card to fade away. Once it disappears completely, the work order’s status is marked as Finished on the MO, and the next work order appears in the Shop Floor module, on the page of the work center where it is configured to be carried out. Any additional work orders can be processed using the instructions detailed in this section.

Clicking Close Production causes the work order card to fade away. Once it disappears, the MO is marked as Done, and the units of the product that were produced are entered into inventory.

After clicking Mark as Done or Close Production, each button is replaced by an Undo button. Click the Undo button before the work order card fades away to keep the work order open.

Tip

This section details the basic workflow for processing an MO in the Shop Floor module. For a more in-depth explanation of the module and all of its features, please see the Shop Floor overview documentation.

Axis Manufacturing allows users to manufacture products using one, two, or three steps. When using three-step manufacturing, Axis creates a pick components transfer, a manufacturing order (MO), and a store finished products transfer, and updates inventory counts based on the number of components removed, and finished products created.

Tip

The number of steps used in manufacturing is set at the warehouse level, allowing for each warehouse to use a different number of steps. To change the number of steps used for a specific warehouse, begin by navigating to , and then select a warehouse from the Warehouses screen.

On the Warehouse Configuration tab, find the Manufacture radio input field, and select one of the three options: Manufacture (1 step), Pick components and then manufacture (2 steps), or Pick components, manufacture and then store products (3 steps).

Important

Products must be properly configured before they can be manufactured in Axis. For details on how to do so, see the documentation on how to configure a product for manufacturing.

Create manufacturing order

To manufacture a product in Axis Manufacturing, begin by navigating to , and then click New to create a new MO.

On the new MO, select the product to be produced from the Product drop-down menu. The Bill of Material field auto-populates with the associated Bill of Materials (BoM).

If a product has more than one BoM configured for it, the specific BoM can be selected in the Bill of Material field, and the Product field auto-populates with the associated product.

After a BoM has been selected, the Components and Work Orders tabs auto-populate with the components and operations specified on the BoM. If additional components or operations are required for the MO being configured, add them to the Components and Work Orders tabs by clicking Add a line.

Finally, click Confirm to confirm the MO.

Process pick components transfer

After confirming a three-step MO, a Transfers smart button appears at the top of the page. Click it to be taken to the Transfers page for the MO. The page lists two transfers: WH/PC/XXXXX (the pick components transfer), and WH/SFP/XXXXX (the store finished products transfer).

Select WH/PC/XXXXX to open the pick components transfer for the MO. This transfer is used to track the movement of components from the locations where they are stored to the location where they are used to manufacture the product.

After transferring the components out of their storage location, click Validate at the top of the transfer, followed by Apply on the Immediate Transfer? pop-up window that appears. Doing so marks the transfer as Done, and updates inventory counts to reflect the quantity of components transferred.

Finally, return to the MO by clicking the WH/MO/XXXXX breadcrumb at the top of the page.

Process manufacturing order

An MO is processed by completing all of the work orders listed under its Work Orders tab. This can be done on the MO itself, or from the work order tablet view.

Basic workflow

To complete work orders from the MO itself, begin by navigating to , and then select a manufacturing order.

On the MO page, select the Work Orders tab. Once work begins on the first work order that needs to be completed, click the Start button for that work order. Axis Manufacturing then starts a timer that keeps track of how long the work order takes to complete.

When the work order is completed, click the Done button for that work order. Repeat the same process for each work order listed on the Work Orders tab.

After completing all of the work orders, click Produce All at the top of the screen to mark the MO as Done, and register the manufactured product(s) into inventory.

Shop Floor workflow

To complete the work orders for an MO using the Shop Floor module, begin by navigating to , and then select an MO.

On the MO, click on the Work Orders tab, and then select the ↗️ (square with arrow coming out of it) button on the line of the first work order to be processed. Doing so opens a Work Orders pop-up window, with details and processing options for the work order.

On the pop-up window, select the Open Shop Floor button at the top-left of the window to open the Shop Floor module.

When accessed directly from a specific work order within an MO, Shop Floor defaults to the page for the work center where the work order is configured to be carried out. The page shows a card for the work order that displays the MO number, the product and number of units to be produced, and the steps required to complete the work order.

A work order is processed by completing each step listed on its card. This can be done by clicking on a step, and following the instructions listed on the pop-up window that appears. Once the step is completed, click Next to move on to the next step, if any are required.

Alternatively, work order steps can be completed by clicking the checkbox that appears on the right side of the step’s line on the work order card. When using this method, the step is automatically marked as completed, without a pop-up window appearing.

The final step on a work order card is titled Register Production. This step is used to register the number of product units that were produced. If the number produced is equal to the number that the MO was created for, click the # Units button on the right side of the line to automatically register that number as the quantity produced.

If a different number must be entered, click the Register Production step to open a pop-up window. Enter the number of units produced in the Units field, and then click Validate to register that number.

Note

The Register Production step appears on every work order card. It must be completed for the first work order that is processed. After doing so, the step appears as already completed for each remaining work order in the MO.

After completing all of the steps for a work order, a button appears on the footer of the work order card. If any other work orders must be completed before the MO can be closed, the button is titled Mark as Done. If there are no additional work orders to complete, the button is titled Close Production.

Clicking Mark as Done causes the work order card to fade away. Once it disappears completely, the work order’s status is marked as Finished on the MO, and the next work order appears in the Shop Floor module, on the page of the work center where it is configured to be carried out. Any additional work orders can be processed using the instructions detailed in this section.

Clicking Close Production causes the work order card to fade away. Once it disappears, the MO is marked as Done, and the units of the product that were produced are entered into inventory.

After clicking Mark as Done or Close Production, each button is replaced by an Undo button. Click the Undo button before the work order card fades away to keep the work order open.

Tip

This section details the basic workflow for processing an MO in the Shop Floor module. For a more in-depth explanation of the module and all of its features, please see the Shop Floor overview documentation.

Process finished product transfer

After completing the MO, return to the order’s Transfers page by clicking the Transfers button at the top of the order. This time, select WH/SFP/XXXXX to open the store finished products transfer. This transfer is used to track the movement of finished products from the location where they were manufactured to the location where they are stored.

After transferring the finished products to their storage location, click Validate at the top of the transfer, followed by Apply on the Immediate Transfer? pop-up window that appears. Doing so marks the transfer as Done, and updates inventory counts to reflect the quantity of finished products transferred.

The ability to accurately calculate the cost of manufacturing a product is critical when determining product profitability. Axis’s Manufacturing app simplifies this calculation by automatically calculating the cost to complete each manufacturing order (MO), as well as the average production cost of a product, based on all completed MOs.

Important

Axis’s Manufacturing app distinguishes between the MO cost and the real cost of an MO.

The MO cost represents how much it should cost to complete an MO, based on the configuration of the product’s bill of materials (BoM). This takes into account the cost and quantity of components, as well as the cost of completing the necessary operations.

The real cost represents how much it actually costs to complete the MO. A few factors can cause the real cost to differ from the MO cost. For example, an operation may take longer to complete than estimated, a greater component quantity might be needed than was specified on the BoM, or the price of components may change during manufacturing.

Cost configuration

Axis computes MO costs based on the configuration of the BoM used to manufacture a product. This calculation includes the cost and quantity of components and operations listed on the BoM, in addition to the operating costs of the work centers where those operations are carried out, and the amount paid to each employee who works on an operation.

Component cost

Component cost is calculated automatically, based on the average purchase cost of a component across all purchase orders (POs). To view a component’s cost, navigate to Inventory app –> Products –> Products, and select a component product. The cost is displayed in the Cost field of the General Information tab, on the component’s product form.

It is possible to set the cost of a component manually, by clicking the Cost field on the component’s product form and entering a value. However, any future POs for the component override a manually entered value, resetting the Cost field back to an automatically computed value.

Work center cost

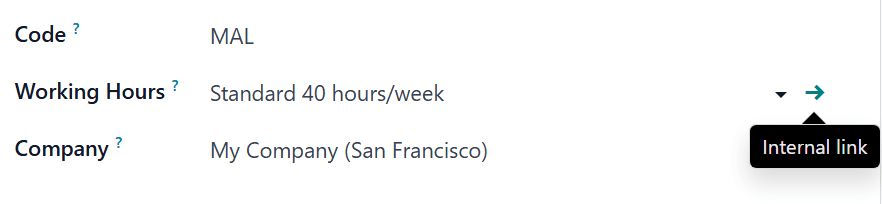

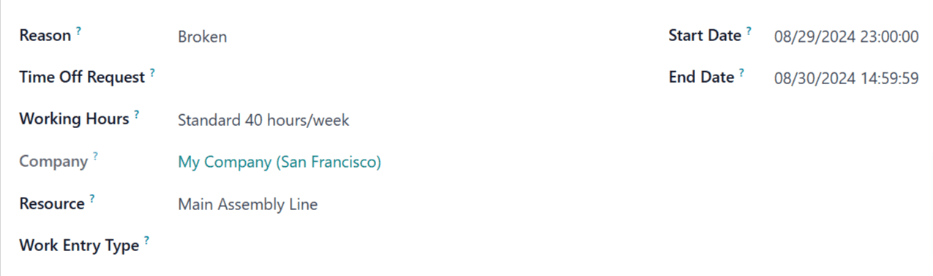

To set the operating cost for a specific work center, navigate to , and select a work center.

To set the cost of operating the work center for one hour, enter a value in the per workcenter field, located beside the Cost per hour section on the work center’s General Information tab.

To set the hourly cost of each employee that operates the work center, enter a value in the

per employee field, located beside the Cost per hour section on the work

center’s General Information tab. For example, if 25.00 is entered in the

per employee field, it costs $25.00 per hour for each employee working at the work

center.

Important

The value entered in the per employee field is only used to calculate the MO cost, which is the estimated cost of completing the MO.

The actual cost of completing the MO is represented by the real cost. Instead of using the value entered in the per employee field, the real cost is calculated using the hourly cost specific to each employee.

For example, if the per employee cost of a work center is ‘$50.00’, and an employee with an hourly cost of ‘$60.00’ completes a work order there, the MO cost (estimated) is calculated using the $50/hr cost, while the real cost is calculated using the $60/hr cost.

See the employee cost section below for information on how to set the cost for specific employees.

Employee cost

To set the hourly cost for a specific employee, navigate to the app, and select an employee. On the employee’s form, select the Settings tab, and enter the employee’s rate in the Hourly Cost field of the Application Settings section.

Important

As detailed in the work center cost section above, the value entered in the Hourly Cost field on the employee’s form is used to calculate the real cost of an MO. The estimated cost of an MO, referred to as the MO cost, uses the per employee cost set on each work center’s form.

BoM configuration

Configuring a BoM so Axis can accurately calculate the cost of MOs that use it requires two steps. First, components must be added, and the required quantity specified. Second, operations must be added, along with the work centers where they are carried out.

Begin by navigating to . Select a BoM, or create a new one by clicking New.

In the Components tab of the BoM form, add each component by clicking Add a line, selecting the component from the drop-down menu in the Component column, and entering the quantity in the Quantity column.

In the Operations tab, add an operation by clicking Add a line to open the Create Operations pop-up window. Enter a title for the operation in the Operation field.

Select the Work Center where the operation is carried out. Then, add a Default Duration, which is the estimated amount of time the operation takes to complete.

By default, the Duration Computation field is set to Set duration manually, which means that the number entered in Default Duration field is always used as the expected duration of the operation.

Selecting Compute based on tracked time causes Axis to automatically compute the Default Duration based on a certain number of work orders, which is set in the Based on field. Before there are work orders to compute this duration, the value in the Default Duration field is used instead.

The hourly cost of operating the work center, and the duration of the operation, are used to calculate the operation’s cost.

Finally, click Save & Close to add the operation to the BoM, and close the Create Operations pop-up window. Alternatively, click Save & New to add the operation to the BoM, and open a blank Create Operations pop-up window to add another operation.

See also

For a full overview of BoM configuration, see the documentation on bills of materials.

MO overview

Each MO has an overview page, which lists a variety of information about the MO, including MO cost and real cost. To view the overview for an MO, navigate to , and select an MO. Then, click the Overview smart button at the top of the MO.

Both the MO cost and real cost take into account the cost and quantity of components, as well as the cost of completing each work order. The overview page lists a row for each of these values, with the sum of them listed at the bottom of the MO Cost and Real Cost columns.

Before work begins on an MO, the MO Cost and Real Cost columns display the same costs. This is the estimated cost of completing the MO.

However, once work commences, the values in the Real Cost column may begin to diverge from the values in the MO Cost column. This happens if a different component quantity is used than was listed on the MO, the duration of a work order is different than expected, or the hourly cost of the employee performing a work order differs from the employee cost set on the work center.

Once the MO has been completed by clicking Produce All, the values in the MO Cost column update to match those displayed in the Real Cost column.

Average manufacturing cost

In addition to the cost of each individual MO for a product, Axis also tracks the average cost of manufacturing the product, taking into account the cost of every completed MO. To view this, navigate to , and select a product.

The manufacturing cost of the product is displayed per unit of measure in the Cost field, located in the General Information tab. The value continues to update as the costs of additional MOs are factored into the average cost.

To the right of the Cost field is a Compute Price from BoM button, which only appears for products with at least one BoM. Click this button to reset the cost of the product to the expected cost, which only takes into account the components and operations listed on the BoM.

Important

Be aware that clicking Compute Price from BoM does not set the price permanently. The cost continues to update based on the average of the BoM price and the real cost of any future MOs.

Example workflow: manufacturing cost

Golf product manufacturer Fairway Fields produces a variety of golf products, including an indoor putting green. They have configured a BoM for the putting green, so Axis automatically calculates the manufacturing cost of each putting green MO.

The BoM lists two components:

One unit of green felt, which costs $20.00.

One unit of a rubber pad, which costs $30.00.

The BoM also lists four operations, all of which are carried out at Assembly Station 1, which has an hourly operating cost of $30.00. Those operations are as follows:

Cut felt: default duration of seven minutes, for a total cost of $3.50.

Cut rubber pad: default duration of five minutes, for a total cost of $2.50.

Attach pad to felt: default duration of 15 minutes, for a total cost of $7.50.

Cut holes: default duration of three minutes, for a total cost of $1.50.

Altogether, the components required to produce one putting green cost $50.00, and the operations required cost $15.00, for a total manufacturing cost of $65.00. This cost is reflected in the Cost field on the putting green’s product form.

Fairway Fields confirms an MO for one putting green. Before manufacturing starts, the MO

overview lists a cost of $65.00 in both the MO Cost and Real Cost

fields.

Manufacturing begins, and the operations take ten minutes longer than expected, for a total

manufacturing time of 40 minutes. This deviation from the BoM is reflected on the MO

overview, which now lists a Real Cost of $70.00.

Once manufacturing is finished, and the MO is marked as Done, the MO overview updates

again, so the values in the MO Cost and Real Cost columns match, each

displaying a value of $70.00.

On the putting green’s product page, the Cost field now displays a cost of $67.50,

the average of the original cost of $65.00 and the real cost of $70.00 from the MO.

In Axis, lot numbers and serial numbers are used to identify and track products in Axis. Serial numbers are used to assign unique numbers to individual products, while lot numbers are used to assign a single number to multiple units of a specific product.

When manufacturing products tracked using lots or serial numbers, Axis requires the lot or serial number to be assigned to each product before manufacturing can be completed. This ensures that each product is properly tracked from the moment it enters inventory.

Configure products for tracking

By default, Axis tracks the quantity of each product on hand, but does not track individual units of a product. Lot or serial number tracking must be enabled for each product individually.

To track a product using lots or serial numbers, begin by navigating to , then scroll down to the Traceability section, and tick the Lots & Serial Numbers checkbox. Finally, click Save to save the change.

Next, click on , and select a product to track. Make sure the Track Inventory checkbox is ticked in the General Information tab. Since lot and serial number functionality is enabled, a drop-down menu appears next to the ticked checkbox.

Click on the Track Inventory drop-down menu. By default, By Quantity is selected, which only tracks the quantity on hand. Select By Lots to track the product using lot numbers, or By Unique Serial Number to track the product using serial numbers.

See also

Lot number manufacturing

To manufacture a product tracked with lots, begin by navigating to . Click New to create a new manufacturing order (MO).

In the Product field, select a product tracked using lots, and enter the desired Quantity. Click Confirm to confirm the MO.

Once the MO is confirmed, a Lot/Serial Number field appears in the top section of the MO form. By default, this field is empty.

To populate the Lot/Serial Number field with a lot number, click the (plus) icon to the right of the field. Doing so automatically generates a lot, using the next available number, and enters it in the field.

Alternatively, click on the Lot/Serial Number field and select an existing lot number, or manually enter a new lot number and click Create “#” in the drop-down menu.

Either of these methods assign the product(s) in the MO a lot number before production is finished. It is also possible to complete production and close the MO by clicking Produce All, without assigning a lot number. Doing so automatically generates and assigns a lot, using the next available number.

Serial number manufacturing

To manufacture a product tracked with serial numbers, begin by navigating to . Click New to create a new MO.

In the Product field, select a product tracked using serial numbers, and enter the desired Quantity. Click Confirm to confirm the MO.

Once the MO is confirmed, a Lot/Serial Number field appears in the top section of the MO form. By default, this field is empty.

The rest of the manufacturing process depends on how many units the MO contains.

Manufacture single unit

If a single unit of the product is being manufactured, clicking Produce All closes the MO, and automatically generates and assigns the next available serial number, which appears in the Lot/Serial Number field.

To assign a serial number without closing the MO, enter a number manually in the Lot/Serial Number field, and click Create “#”, or click the (plus) icon to the right of the field to auto-fill it with the next available number.

Manufacture multiple units

Important

When manufacturing a product tracked using serial numbers, an MO can be created for multiple units. However, when serial numbers are assigned to each unit, either at the end of production or before, the MO is split into multiple MOs, each containing one unit of the product.

Each of the split MOs is identified by a numerical tag added to the end of the original MO number.

Example

MO WH/MO/00109 contains two units of a Chair, a product tracked using serial numbers. A

serial number is assigned to each unit of the chair. This causes the MO to be split into two

MOs, each containing one unit of the chair. The MOs are titled WH/MO/00109-001 and

WH/MO/00109-002.

To assign serial numbers to each unit of an MO, click Produce All to open the Batch Production pop-up window.

The First Lot/SN field of the pop-up window is auto-filled with the next available serial number. The Number of SN field defaults to the number of units being manufactured. The values of either field can be changed manually.

Click Generate to generate the specified number of serial numbers, beginning with the number entered in the First Lot/SN field. The serial numbers are displayed in the text box at the bottom of the pop-up window, and can be manually changed after generation.

To assign serial numbers without completing production, click the Prepare MO button. Doing so splits the MO into individual MOs, one for each unit in the original MO. Each MO is left open, and can be closed individually.

To assign serial numbers and complete production, click the Produce button. Doing so splits the MO into individual MOs, one for each unit in the original MO. All of the MOs are closed, since production is complete.

After clicking Prepare MO or Produce, the app

automatically shows the first of the split MOs (ex. WH/MO/00109-001). To view and access the

rest the split MOs, click the Backorders smart button at the top of the screen.

In Axis’s Manufacturing app, the master production schedule (MPS) is used to manually plan manufacturing orders (MOs) and purchase orders (POs), based on forecasted quantities of products and components.

By considering the impact of confirmed MOs and POs, along with manually adjusted demand forecasts, the MPS can be used to manage long-term product replenishment. This ensures the continued availability of the necessary products and components.

Since the MPS allows for manual intervention, it is useful for replenishing products where the demand of existing sales orders (SOs) does not reflect probable future demand.

Example

A retail store sells artificial Christmas trees during the holiday season. It is currently September, and the store has less than ten Christmas tree MOs confirmed for the month of December.

Despite the number of confirmed MOs, the procurement manager knows that the demand for Christmas trees in December is going to be much higher, once the holiday season starts. As a result, they manually enter a greater demand in the MPS, so they can properly replenish the product in time for the increase in customer demand.

Important

It is essential to remember that the MPS is a MANUAL tool. Adding a product to the MPS does not cause it to be manufactured or purchased automatically. The MPS simply suggests the amount of the product that should be replenished, but requires user input to create the MOs or POs that are used to replenish it.

For this reason, it is recommended that the MPS NOT be used alongside reordering rules for the same product. Because reordering rules are an automated workflow, they conflict with the manual replenishment method of MPS. Using both, in unison, can lead to inaccurate forecasts and the creation of unnecessary replenishment orders.

Enable and configure MPS

To use the MPS feature, navigate to , and tick the Master Production Schedule checkbox in the Planning section. Finally, click Save.

After enabling the Master Production Schedule feature, two new fields appear under it on the Settings page: Time Range and Number of Columns.

The Time Range field is used to select the period of time over which planning takes place, and offers three options: Monthly, Weekly, and Daily. For example, if Monthly is selected, the MPS plans the production requirements of products and components on a monthly basis.

The Number of Columns field is used to specify the quantity of the selected

Time Range units shown on the MPS page. For example, if the Time Range

field is set to Monthly, and 12 is entered in the Number of Columns field,

the MPS shows one column for the next 12 months, starting with the current month.

If the values of the Time Range or Number of Columns fields are altered, click Save again to save the changes.

MPS dashboard

To open the MPS, navigate to . The MPS view appears as follows:

The grey column on the left side of the screen shows a section for every product added to the MPS, with each product section being broken down into smaller rows. The information shown in the rows depends on the filters selected in the Search… bar drop-down menu at the top of the page. The default categories that appear in the rows are:

[Product] by [unit] : the forecasted stock quantity at the beginning of each time period. [Product] and are selectable buttons which open the product’s page, or the forecast report for the product, respectively.

- Forecasted Demand: the demand forecast, which is entered manually. This represents an estimate of the demand for the product during each time period.

- Indirect Demand Forecast: while this is a default category, it only appears for products that are components of other products. It represents the demand for the component from existing MOs.

+ Suggested Replenishment: the quantity of the product that is suggested to be replenished through MOs or POs. To the right of the category title is a Replenish button, which is used to manually replenish the product, based on the quantity suggested to be replenished.

The “Replenish” button on the “+ Suggested Replenishment” row.

= Forecasted Stock: the quantity of the product forecasted to be in stock at the end of each time period, assuming that suggested replenishment numbers are fulfilled.

Altogether, these default categories form an equation:

In the case of components, the Indirect Demand Forecast is taken into account as well.

The - Forecasted Demand and + Suggested Replenishment fields can be edited for any of the time periods to the right of the product column. Doing so changes the equation, and updates the value displayed in the Forecasted Stock field.

Changing the value in the + Suggested Replenishment field also makes an (reset) button appear to the left of the field. Click the (reset) button next to the field to reset its value back to the one calculated by the MPS.

Important

While the MPS can be used with only the default categories enabled, it is advisable to also enable the Actual Demand category. This is done by clicking the (down arrow) on the right side of the Search… bar, and enabling the Actual Demand option under the Rows header.

With the Actual Demand option enabled, the - Forecasted Demand category changes to the - Actual / Forecasted Demand category. In addition to the manually entered forecasted demand, this category also displays the confirmed demand for the product, which is based on confirmed SOs.

Each column to the right of the products column lists one unit of the time period selected in the Time Range field on the Manufacturing app Settings page (ex. months). The number of time period columns corresponds to the value entered in the Number of Columns field.

The first time period column represents the current time period. For example, if the MPS is configured to use months, the first column displays data for the current month. On this first column, the + Suggested Replenishment field appears in one of five colors:

Green: a replenishment order must be generated to keep stock at the Safety Stock Target.

Gray: a replenishment order has already been generated to keep stock at the Safety Stock Target.

Orange: a replenishment order has already been generated, but the quantity it was created for is not enough to keep stock at the Safety Stock Target.

Red: a replenishment order has already been generated, but the quantity it was created for puts the amount of stock above the Safety Stock Target.

The + Suggested Replenishment field appears white, if no replenishment order has been generated, and it is not necessary to generate one at the current moment.

Add a product

To use MPS to manage the replenishment of a product, navigate to . At the top of the MPS page, click Add a Product to open the Add a Product pop-up window.

Important

Products must be properly configured to be replenished through the MPS.

In the case of manufactured products, the Manufacture route must be selected in the Routes section of the Inventory tab, on the product’s form.

In the case of products that are purchased, the Buy route must be selected in the Routes section of the Inventory tab, on the product’s form. Additionally, a vendor and the price they sell the product for must also be specified on the Purchase tab.

On the pop-up window, select the product to add in the Product drop-down menu. If the product is replenished through manufacturing, select the product’s BoM in the Bill of Materials field.

Note

Selecting a BoM when adding a product to the MPS also adds any components listed on the BoM. If it is not necessary to manage the replenishment of components through the MPS, simply leave the Bill of Materials field blank.

If the database is configured with multiple warehouses, a Production Warehouse field appears on the Add a Product pop-up window. Use this field to specify which warehouse the product is replenished to.

In the Safety Stock Target field, specify the minimum quantity of the product that

should be kept available for orders at all times. For example, if there should always be 20 units of

the product available for order fulfillment, enter 20 in the Safety Stock Target

field.

In the Minimum to Replenish field, enter the minimum product quantity for orders created

to replenish the product. For example, if 5 is entered in this field, replenishment orders for the

product include a minimum of five units.

In the Maximum to Replenish field, enter the maximum product quantity for orders created

to replenish the product. For example, if 100 is entered in this field, replenishment orders for

the product include a maximum of 100 units.

Finally, click Save to add the product to the MPS. The product now appears on the MPS page each time it is opened. If a BoM was selected in the Bill of Materials field of the Add a Product pop-up window, any components listed on the BoM appear on the page, as well.

Edit a product

After adding a product to the MPS, it may be necessary to change the replenishment values entered on the Add a Product pop-up window. To do so, click the # ≤…≤ # button to the immediate right of the Replenish button, on the + Suggested Replenishment row, below the product’s name.

Note

The first and second number displayed on the # ≤…≤ # button correspond to the values entered in the Minimum to Replenish and Maximum to Replenish fields when adding the product to the MPS.

For example, if 5 was entered in the Minimum to Replenish field, and 100 was

entered in the Maximum to Replenish field, the button appears as 5 ≤…≤

100.

Clicking the # ≤…≤ # button opens the Edit Production Schedule pop-up window. This pop-up window is the same as the Add a Product pop-up window, except that the Product and Bill of Materials fields cannot be edited.

On the Edit Production Schedule pop-up window, enter the desired values in the Safety Stock Target, Minimum to Replenish, and Maximum to Replenish fields. Then, click Save to save the changes.

Remove a product

To remove a product from the MPS, tick the checkbox to the left of its name. Then, click the Actions button at the top of the screen, and select Delete from the resulting drop-down menu. Finally, click Ok on the Confirmation pop-up window.

Deleting a product from the MPS removes it, along with all of its data. If the product is re-added, its replenishment values must be reconfigured.

MPS replenishment

Products in the MPS can be replenished in one of three ways:

Click the Replenish button at the top of the screen to generate replenishment orders for every product below its Safety Stock Target for the current month.

Click the Replenish button on the right side of the + Suggested Replenishment row of a specific product, to generate a replenishment order for that specific product.

Tick the checkbox to the left of the product name of one or more products. Then, click the Actions button at the top of the screen, and select Replenish from the resulting drop-down menu. Doing so generates a replenishment order for each selected product.

The type of replenishment order generated corresponds to the route selected on the Inventory tab of the product’s form:

If the Buy route is selected, an RfQ is generated to replenish the product. RfQs can be selected by navigating to the app. Any RfQ generated by the MPS lists MPS in its Source Document field.

If the Manufacture route is selected, an MO is generated to replenish the product. MOs can be selected by navigating to . Any MO generated by the MPS lists MPS in its Source Document field.

When manufacturing certain products, it is common to be left with residual materials, in addition to the finished product. These materials are known as by-products. By specifying the by-products created during manufacturing on a product’s bill of materials (BoM), the quantity of by-products on-hand is tracked by Axis.

Example

Manufacturing a rocking chair requires ten pieces of wood. During production, five pieces of scrap wood are created, in addition to the rocking chair. By designating the scrap wood as a by-product on the rocking chair’s BoM, Axis tracks the on-hand count of scrap wood, as well as the quantity of rocking chairs produced.

Configuration

To specify by-products on a product’s BoM, the By-Products setting must be enabled. To do so, navigate to , and tick the By-Products checkbox, located under the Operations heading. Then, click Save to apply the change.

With the By-Products setting enabled, a By-products tab appears on product BoMs.

Add byproduct to BoM

To add by-products to a BoM, navigate to , and select a BoM.

On the BoM, select the By-products tab. Click Add a line, and select the by-product in the By-product drop-down field. In the Quantity field, enter the quantity of the by-product produced during manufacturing.

If the by-product is produced during a specific operation of a manufacturing order (MO), select the operation in the Produced in Operation field. For example, if a scrap wood by-product is produced during an Assemble operation, select that operation in the Produced in Operation field.

Manufacture by-product

When an MO is completed and marked as Done, Axis registers the quantity of by-products created during the manufacturing process. To create a new MO, navigate to , and click New.

In the Bill of Material field, select a BoM on which by-products have been specified. After doing so, the Product field auto-populates with the corresponding product. Click Confirm to confirm the MO.

When manufacturing is completed, click the Produce All button at the top of the MO. After doing so, inventory counts update to reflect the quantity of by-product(s) produced, as well as the quantity of the product.

Click the Product Moves smart button at the top of the MO page to see the movements of components and products. Each by-product is listed on the resulting Inventory Moves page, with the From column displaying the virtual production location, and the To column displaying the location where the by-product is stored.

During the manufacturing process, scrapping components or finished products may be necessary when items are damaged, defective, or no longer usable.

Tracking scrapped materials helps manufacturers monitor waste, identify process issues, and account for production costs.

In Axis, scrapped items are removed from physical inventory and moved to a virtual location called Virtual Locations/Scrap. This location is not a physical space—it is a way to log and track losses without affecting real stock levels.

See also

Tip

Scrap orders can be viewed by navigating to . Each scrap order shows the date and time the order was created, along with the product and quantity that was scrapped.

To view the total quantity of each item scrapped, navigate to , then remove the Internal filter from the Search… bar to display all virtual locations. From the list, select the Virtual Locations/Scrap location.

Manufacturing app

To scrap a product from the Manufacturing app, go to and select the desired MO.

On the MO, click the (Actions) icon, then choose Scrap from the drop-down menu.

Shop Floor

In Shop Floor, only components can be scrapped. Navigate to the desired MO card, and then tap the (Actions) icon and in the What do you want to do? pop-up window, select Scrap.

Scrap pop-up window

After opening the Scrap Products pop-up window using one of the methods detailed above, select the component or finished product being scrapped, from the Product drop-down menu.

In the Quantity field, enter the quantity being scrapped.

By default, the Source Location field is set to the warehouse’s pre-production location, while the Scrap Location field is set to the Virtual Locations/Scrap location. If either the source or scrap location should be changed, select a different location from their respective drop-down menus.

Enable the Replenish Scrapped Quantities checkbox if a picking order should be created to replace the scrapped component upon confirmation of the scrap order. This option should only be enabled for warehouses with two-step or three-step manufacturing enabled, since components are not picked as part of the one-step manufacturing process.

After filling out the Scrap Products pop-up window, click the Scrap Products button. After one or more scrap orders have been created, a Scraps smart button appears at the top of the screen. Click it to view a list of all scrap orders for the MO.

In some cases, it is necessary to dismantle manufactured products into their individual components. This may be required if too many units of a product were built, or if the components of one product must be reclaimed to use in the manufacturing of another.

In Axis Manufacturing, products can be dismantled, and their components returned to inventory, using unbuild orders. By using unbuild orders to accomplish this task, inventory counts for the finished product and its components remain accurate, based on the quantity of products dismantled, and the quantity of components reclaimed.

Create unbuild order

A new unbuild order can be created by navigating to , and clicking New.

Begin filling out the new unbuild order by selecting a Product to unbuild. After doing so, the Bill of Material field auto-populates with the corresponding bill of materials (BoM). If a different BoM should be used, click on the Bill of Material field, and select it from the drop-down menu.

Alternatively, a specific BoM can be selected in the Bill of Material field before selecting a product, which causes the corresponding product to auto-populate in the Product field.

Next, specify the Quantity of the product that is being unbuilt.

If the product being unbuilt was originally manufactured in a specific manufacturing order (MO), select it in the Manufacturing Order field.

In the Source Location field, select the location where the product being unbuilt is currently stored.

In the Destination Location field, select the location where the reclaimed components are stored after the unbuild order is completed.

If the Lots & Serial Numbers feature is enabled in the settings of the Inventory app, a Lot/Serial Number field appears on the unbuild order, which can be used to specify the lot(s) or serial number(s) of the product being unbuilt, if any are assigned.

If the Axis database has been configured with multiple companies, a Company field appears on the unbuild order, which can be used to specify the company that owns the product being unbuilt.

Finally, once the product has been unbuilt, click the Unbuild button at the top of the order to confirm that it has been completed.

Warning

While it is possible to create unbuild orders for products that have zero (or fewer) units on-hand, this is not advised, since it can lead to inventory inconsistencies.

If an unbuild order is created for a product with zero (or fewer) units on-hand, a pop-up window appears, warning the user that there is an insufficient quantity to unbuild.

To ignore the warning, and proceed with the unbuild order, click Confirm at the bottom of the pop-up window. To return to the unconfirmed unbuild order, click Discard, instead.

After completing an unbuild order, inventory counts automatically update, based on the quantity of products unbuilt, and the quantity of components reclaimed.

Example

A Coat Rack product is comprised of one Wooden Pole component and six Wooden Dowel

components.

An unbuild order is created for one unit of the Coat Rack. Once the order is completed, the

on-hand quantity of Coat Racks decreases by one, while the on-hand quantities of Wooden Poles

and Wooden Dowels increase by one and six, respectively.

Scrap unusable components

In some cases, components may be unusable after the unbuilding process is completed. To ensure that inventory counts accurately reflect the quantity of usable components on-hand, any component that can no longer be used should be removed from inventory using a scrap order.

In some cases, the full quantity of a manufacturing order cannot be produced immediately. When this happens, Axis Manufacturing allows for the manufacturing of partial quantities of the order and creates a backorder for the remaining amount.

In the Manufacturing app, creating a backorder splits the original manufacturing order into two orders. The reference tag for each order is the tag used for the original order, followed by a hyphen and then an additional number to indicate that it’s a backorder.

Example

A company creates a manufacturing order with the reference tag WH/MO/00175, for 10 units of Product X. After starting work on the manufacturing order, the employee working the production line realizes there are only enough components in stock to produce five units of the product.

Instead of waiting for additional stock of the components, they manufacture five units and create a backorder for the remaining five. This splits the manufacturing order into two separate orders: WH/MO/00175-001 and WH/MO/00175-002.

Order 001 contains the five units that have been manufactured, and is immediately marked as Done. Order 002 contains the five units that still need to be manufactured and is marked as In Progress. Once the remaining components are available, the employee returns to order 002 and manufactures the remaining units before closing the order.

Create a manufacturing backorder

To create a backorder for part of a manufacturing order, begin by navigating to . Select a manufacturing order with a quantity of two or more or create one by clicking Create.

If a new manufacturing order is created, select a product from the Product drop-down menu and enter a quantity of two or more in the Quantity field, then click Confirm to confirm the order.

After manufacturing the quantity that is being produced immediately, enter that number in the Quantity field at the top of the manufacturing order.

Next, click Validate, and a You produced less than initial demand pop-up window appears, from which a backorder can be created. Click Create Backorder to split the manufacturing order into two separate orders, with the reference tags WH/MO/XXXXX-001 and WH/MO/XXXXX-002.

Order 001 contains the items that have been manufactured, and is closed immediately. Order 002 is the backorder that contains the items that have yet to be manufactured, and remains open, to be completed at a later date.

Once the remaining units can be manufactured, navigate to , and then select the backorder manufacturing order. If all of the remaining units are manufactured immediately, simply click Validate to close the order.

If only some of the remaining units are manufactured immediately, create another backorder for the remainder by following the steps detailed in this section.

Create a backorder in Shop Floor

Backorders for manufacturing orders can also be created from the Shop Floor module.

Note

In order to use the Shop Floor module, the Work Orders setting must be enabled. To do so, navigate to , enable the Work Orders checkbox, and then click Save.

To create a backorder from the Shop Floor module, begin by navigating to . Select an MO for multiple units of a product, for which a backorder needs to be created.

On the MO, select the Work Orders tab, and then click the Open Work Order (external link icon) button on the line of the work order to be processed. On the resulting Work Orders pop-up window, click the Open Shop Floor button to open the Shop Floor module.

When accessed from a specific work order, the Shop Floor module opens to the page for the work center where the order is configured to be processed, and isolates the work order’s card so that no other cards are shown.

Complete the steps on the work order’s card until the Register Production step is reached, and then click on it to open the Register Production pop-up window.

Important

Do not click the # Units button on the right side of the step. Doing so automatically registers the full amount of units as having been produced.

On the Register Production pop-up window, enter the number of units produced in the Quantity field. Make sure the number entered is less than the number of units listed to the right of the field. Then, click Validate.

The pop-up window disappears and the # Units button on the work order’s card updates to reflect the number of units produced, as a fraction of the number of units for which the MO was originally created.

Next, click the Mark as Done button at the bottom-right of the work order’s card. The

work order card begins to fade away. Once it disappears completely, a new work order card appears,

titled with the original MO’s reference number with a -002 tag added to the end of it.

This new reference number represents the backorder MO. The original MO’s reference number now

appears with a -001 tag added to the end of it to distinguish it from the backorder MO.

If the original MO has no remaining work orders, it can be closed by selecting the All filter in the top navigation of the Shop Floor module, and then clicking Close Production at the bottom of the MO’s card.

If the original MO has remaining work orders that must be completed before it can be closed, cards for these work orders appear on the Shop Floor pages for the work centers where they are configured to be carried out. They can be processed as normal, and additional backorders can be created from their work order cards using the instructions detailed in this section.

Once the current work order for the backorder MO is ready to be processed, this can also be completed as normal, and an additional backorder can be created from its work order card by following the instructions detailed in this section.

After the final work order for the backorder MO has been completed, the MO can be closed by clicking the Close Production button at the bottom of the work order’s card.

In Axis Manufacturing, it is possible to create manufacturing orders for a single unit of an item, or multiple units of the same item. In some cases, it may be necessary to split a manufacturing order that contains multiple units into two or more orders, or to merge two or more orders into a single order.

Important

A manufacturing order can only contain one unit of a product, or multiple units of a single product that all use the same Bill of Materials (BoM). As a result, it is only possible to merge manufacturing orders when every order contains the same product being manufactured with the same BoM.

Split manufacturing orders

To split a manufacturing order into multiple orders, begin by navigating to , then select a manufacturing order. At the top of the page, next to the New button, the manufacturing order’s reference number appears with a ⚙️ (settings) button next to it.

Click the ⚙️ (settings) button to open the general settings for the manufacturing order, then select Split.

After selecting Split, a Split production pop-up window appears. In the Split # field, enter the number of manufacturing orders that the original order should be split into, then click outside of the field. A table appears below, with a line for each new manufacturing order that will be created by the split. In the Quantity To Produce column, enter the number of units that will be assigned to each new manufacturing order. Finally, click Split to split the manufacturing order.

After clicking Split, the original manufacturing order is split into the number of orders that was specified in the Split # field. The reference numbers for the new manufacturing orders are the reference number for the original order with -### tags added to the end.

Example

Manufacturing order WH/MO/00012 is split into three separate orders. The reference numbers for the new orders are WH/MO/00012-001, WH/MO/00012-002, and WH/MO/00012-003.

Merge manufacturing orders

To merge two or more manufacturing orders into a single order, begin by navigating to . Select the manufacturing orders that will be merged by activating the checkbox to the left of the name of each order.

Once all manufacturing orders have been selected, click the Actions button at the top of the page, then select Merge from the drop-down menu.

The selected manufacturing orders are merged into a single order. The reference number for the new manufacturing order is the next sequential number that has not already been assigned to an order.

Example

The last reference number used for a manufacturing order was WH/MO/00012. Two manufacturing orders, WH/MO/00008 and WH/MO/00009, are merged into a single order. The reference number for the manufacturing order created by the merger is WH/MO/00013.

In the Source field for the manufacturing order created by the merger, the reference numbers of the manufacturing orders that were merged are listed.

Example

Manufacturing orders WH/MO/00009 and WH/MO/00010 are merged to create WH/MO/00011. The source field for WH/MO/00011 lists both WH/MO/00009 and WH/MO/00010.

Continuous improvement is a general philosophy intended to help individuals and organizations constantly improve themselves and the work they produce.